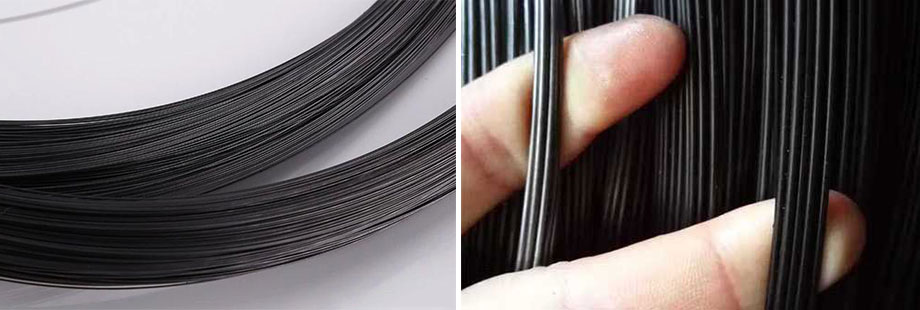

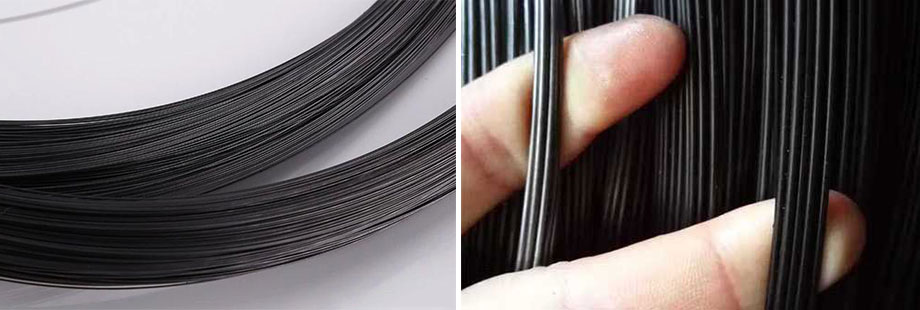

Music Spring Wire is a high-quality high-carbon steel wire originally named for its use as the core material in the strings of stringed instruments such as pianos and violins. Due to its widespread application in the manufacture of high-stress springs, it has come to be known as “spring Music Spring Wire.” Its core characteristics stem from strict process control, achieved through precise smelting, multiple drawing processes, and heat treatment, resulting in exceptionally high tensile strength, elastic limit, and toughness, making it the material of choice in the precision spring industry.

Music wire springs: These elastic components are manufactured using music wire as raw material, undergoing critical processes such as coiling, forming, and heat treatment to enhance strength. These springs combine high load-bearing capacity with excellent elastic recovery properties, making them particularly suitable for applications with stringent requirements for precision, fatigue life, and environmental adaptability.

Stainless steel springs: These elastic components are manufactured using stainless steel wire as raw material. Their core advantage lies in their outstanding corrosion resistance, while also offering sufficient elasticity and strength. These springs are widely used in corrosive environments, effectively addressing the rusting issues that ordinary springs encounter in harsh operating conditions.

Advantages of Music Spring Wire:

1. High strength and high elasticity: With a tensile strength range of 1600–2800 MPa, it significantly outperforms ordinary steel wire. Even under prolonged high-stress working conditions, it can maintain its elasticity stably, greatly reducing the likelihood of permanent deformation.

2. Toughness and fatigue resistance: After being optimized through special processing techniques, it maintains hardness while enhancing toughness. Even in scenarios with frequent stress, it effectively resists the risk of fracture, significantly extending the service life of springs.

3. Dimensional Accuracy and Surface Quality: Wire diameter tolerances are strictly controlled within ±0.01 mm, with extremely low surface roughness, ensuring that the resulting springs exhibit high precision and excellent consistency, meeting the stringent elasticity requirements of precision equipment.

4. Cost-effectiveness advantage: Compared to certain alloy steel wires, Music Spring Wire offers more competitive production costs while meeting the same strength requirements, making it particularly suitable for large-scale, high-volume applications where cost control is a priority.

Three common types of materials for metal spiral springs

| Material type | Key ingredients | Key features | Typical application scenarios |

| Music Spring Wire | High carbon steel (carbon content 0.60%-1.05%) | High strength, high elasticity, long fatigue life | Automotive valve springs, clutch springs, precision instrument springs |

| Stainless steel wire | 304/316/17-7PH stainless steel, etc. | High corrosion resistance, moderate elasticity and strength, and partial high temperature resistance. | Medical device springs, food machinery springs, outdoor equipment springs |

| Chromium-silicon alloy steel wire | Chromium (Cr) and silicon (Si) alloyed carbon steel | High temperature resistance (200-300°C), good creep resistance, high strength | High-temperaturespringsforengines,high-pressurespringsforconstructionmachinery |

The core difference between stainless steel springs and Music Spring Wire springs

| Comparison dimensions | Music Spring Wire spring | Stainless steel spring |

| Core material | High carbon steel (Music Spring Wire) | Stainless steel (such as 304, 316, 17-7PH) |

| Corrosion resistance | Poor, prone to rust, requires additional electroplating (such as zinc plating or nickel plating) for protection. | Excellent, can be used for a long time in humid, acidic, and alkaline environments without additional preservation. |

| Strength and elasticity | Higher, greater elastic limit, suitable for high-load scenarios | Medium, lower strength than Music Spring Wire, suitable for low to medium load scenarios |

| High temperature Resistance | General (long-term operating temperature ≤ 120°C) | Some models are outstanding (e.g., 17-7PH Can withstand 315°C). |

| Cost | Lower (raw materials + before subsequent anti-corrosion treatment) | Higher (high cost of stainless steel raw materials) |

| Typical applications | Automotive suspension springs, precision compression springs, valve springs | Bathroomhardwaresprings,medicalsyringesprings,marineequipmentsprings |

View document

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek