The pure copper wire is made of 4N high-purity copper material by adding trace elements. It has low ball hardness and wire hardness, excellent electrical and thermal conductivity, and good surface anti-oxidation performance. It is suitable for the packaging of semiconductor discrete devices and various integrated circuits (ICs).

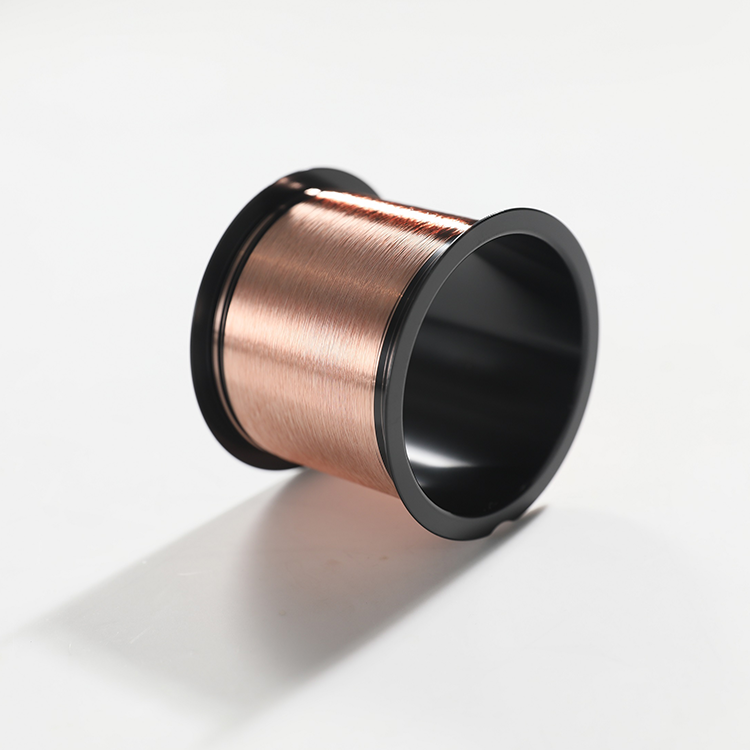

Copper Bonding Wire

| Type | φ Diameter±1% um | Breaking Load BL(gf) | Elongation EL(%) | Length Meters |

| Pure copper wire | 18(0.7mil) | 5-8 | 5-15 | 500/1000 |

| 20(0.8mil) | 6-10 | 5-15 | 500/1000 |

| 23(0.9mil) | 8-13 | 7-17 | 500/1000 |

| 25(1.0mil) | 9-15 | 7-17 | 500/1000 |

| 30(1.2mil) | 14-19 | 11-21 | 500/1000 |

Pure Copper Wire (Bonding Copper Wire):

Low Cost: Compared with bonding gold wire, the price of copper is relatively cheap, which can significantly reduce the production costs of industries such as semiconductor packaging. For example, the cost of a copper wire with a diameter of φ0.020mm can be saved by about 63% compared with that of a gold wire.

Excellent Mechanical Properties: Bonding copper wire has a high elongation rate and breaking force. The high breaking force enables the copper wire to withstand higher stress, and the high elongation rate allows the copper wire to form a good arc shape during the bonding process, which can avoid the phenomenon of wire collapse and improve the reliability of the device. When the same welding strength is met, a thinner copper wire can be used to replace the gold wire, reducing the lead bonding pitch and meeting the production requirements of highly integrated devices.

Good Electrical and Thermal Conductivity: Copper has a high electrical conductivity, with a relatively low resistivity of 1.6μΩ/cm. Its electrical conductivity is nearly 40% higher than that of gold and nearly twice as high as that of aluminum. When carrying the same current, the cross-section of the copper wire is smaller. Its thermal conductivity is also about 20% higher than that of gold. Reducing the diameter of the welding wire is more conducive to heat dissipation. Moreover, the thermal expansion coefficient of the copper wire is higher than that of the gold wire, and the stress at the solder joint is lower, reducing the possibility of the neck fracture of the solder joint in the later stage.

Good Bonding Performance: During the bonding process, the copper wire has good adhesion performance with the chip and the substrate. Moreover, the growth rate of the intermetallic compound in the copper wire solder joint is significantly lower than that in the gold wire solder joint. The contact resistance is low, and less heat is generated, which can improve the bonding strength and welding reliability.

Application Fields of Pure Copper Wire:

Semiconductor Packaging: It is a commonly used internal lead material in the microelectronic packaging of semiconductor discrete devices, integrated circuits, etc., and is used to realize the electrical connection between the chip and the lead frame. It also has good application potential in the fields of high-end products such as leadless packaging and small-pitch pads.

Electronic Component Manufacturing: In the manufacturing of electronic components such as resistors, capacitors, and inductors, it is used to connect the electrodes and pins of the components to ensure the normal operation of the components.

Hot Tags: China,custom , Pure copper wire (bonded copper wire) , manufacturer,factory,supplier

Contact us with any questions

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek