Introduction to Materials

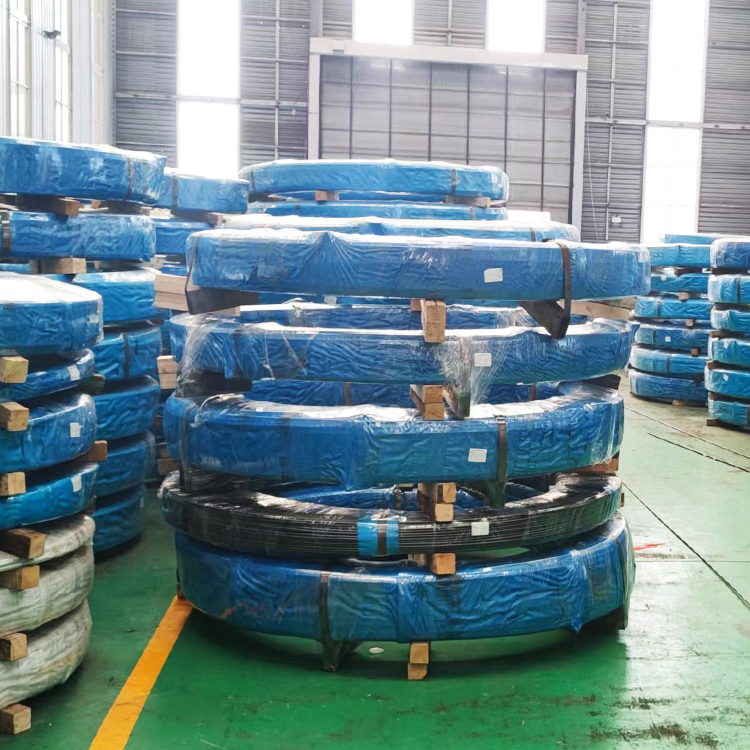

Steel wire grades 65Mn, 60Si2MnA, the material has high strength, elastic limit, yield ratio, hardenability and temper resistance stability, very wide use, mostly used in some important springs and wear serious wear under fatigue performance in higher stress, such as spring ring, shock absorber spring and brake spring, automobile, locomotive, tractor coil spring, Cylinder safety valve spring and some mechanical wear bar, etc.

Spring wire for shock absorber

|

Spring steel wire for crusher |

Spring wire for car suspension |

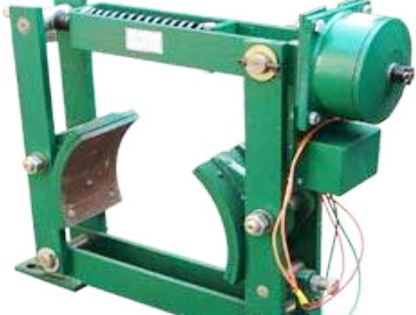

Spring wire for brake |

Mechanical properties

Table of mechanical properties of static level and medium fatigue level (the strength of the same plate is not greater than 50MPa)

| Diameter(mm) | Tensile Strength(MPa) | Reduction of area/%≥ |

| FDC | FDCrV-A | FDCrV-B | FDSi Mn | FDSiCr |

| TDC | TDCrV-A | TDCrV-B | TDSiMn | TDSiCr | FD | TD |

| 0.50 - 0.80 | 1800 - 2100 | 1800 - 2100 | 1900 - 2200 | 1850 - 2100 | 2000 - 2250 | - |

| 0.80 - 1.00 | 1800 - 2060 | 1780 - 2080 | 1860 - 2160 | 1850 - 2100 | 2000 - 2250 | - |

| 1.00 - 1.30 | 1800 - 2010 | 1750 - 2010 | 1850 - 2100 | 1850 - 2100 | 2000 - 2250 | 45 | 45 |

| 1.30 - 1.40 | 1750 - 1950 | 1750 - 1990 | 1840 - 2070 | 1850 - 2100 | 2000 - 2250 | 45 | 45 |

| 1.40 - 1.60 | 1740 - 1890 | 1710 - 1950 | 1820 - 2030 | 1850 - 2100 | 2000 - 2250 | 45 | 45 |

| 1.60 - 2.00 | 1720 - 1890 | 1710 - 1890 | 1790 - 1970 | 1820 - 2000 | 2000 - 2250 | 45 | 45 |

| 2.00 - 2.50 | 1670 - 1820 | 1670 - 1830 | 1750 - 1900 | 1800 - 1950 | 1970 - 2140 | 45 | 45 |

| 2.50 - 2.70 | 1640 - 1790 | 1660 - 1820 | 1720 - 1870 | 1780 - 1930 | 1950 - 2120 | 45 | 45 |

| 2.70 - 3.00 | 1620 - 1770 | 1630 - 1780 | 1700 - 1850 | 1760 - 1910 | 1930 - 2100 | 45 | 45 |

| 3.00 - 3.20 | 1600 - 1750 | 1610 - 1760 | 1680 - 1830 | 1740 - 1890 | 1910 - 2080 | 40 | 45 |

| 3.20 - 3.50 | 1580 - 1730 | 1600 - 1750 | 1660 - 1810 | 1720 - 1870 | 1900 - 2060 | 40 | 45 |

| 3.50 - 4.00 | 1550 - 1700 | 1560 - 1710 | 1620 - 1770 | 1710 - 1860 | 1870 - 2030 | 40 | 45 |

| 4.00 - 4.20 | 1540 - 1690 | 1520 - 1670 | 1590 - 1740 | 1690 - 1840 | 1850 - 2000 | 40 | 45 |

| 4.50 - 4.70 | 1510 - 1660 | 1510 - 1660 | 1580 - 1730 | 1680 - 1830 | 1840 - 1990 | 40 | 45 |

| 4.70 - 5.00 | 1500 - 1650 | 1500 - 1650 | 1560 - 1710 | 1670 - 1820 | 1830 - 1980 | 40 | 45 |

| 5.00 - 5.60 | 1470 - 1620 | 1460 - 1610 | 1540 - 1690 | 1660 - 1810 | 1800 - 1950 | 35 | 40 |

| 5.60 - 6.00 | 1460 - 1610 | 1440 - 1590 | 1520 - 1670 | 1650 - 1800 | 1780 - 1930 | 35 | 40 |

| 6.00 - 6.50 | 1440 - 1590 | 1420 - 1570 | 1510 - 1660 | 1640 - 1790 | 1760 - 1910 | 35 | 40 |

| 6.50 - 7.00 | 1430 - 1580 | 1400 - 1550 | 1500 - 1650 | 1630 - 1780 | 1740 - 1890 | 35 | 40 |

| 7.00 - 8.00 | 1400 - 1550 | 1380 - 1530 | 1480 - 1630 | 1620 - 1770 | 1710 - 1860 | 35 | 40 |

| 8.00 - 9.00 | 1380 - 1530 | 1370 - 1520 | 1470 - 1620 | 1610 - 1760 | 1700 - 1850 | 30 | 35 |

| 9.00 - 10.00 | 1360 - 1510 | 1350 - 1500 | 1450 - 1600 | 1600 - 1750 | 1660 - 1810 | 30 | 35 |

| 10.00 - 12.00 | 1320 - 1470 | 1320 - 1470 | 1430 - 1580 | 1580 - 1730 | 1660 - 1810 | 30 | - |

| 12.00 - 14.00 | 1280 - 1430 | 1300 - 1450 | 1420 - 1570 | 1560 - 1710 | 1620 - 1770 | 30 | - |

| 14.00 - 15.00 | 1270 - 1420 | 1290 - 1440 | 1410 - 1560 | 1550 - 1700 | 1620 - 1770 | - |

| 15.00 - 17.00 | 1250 - 1400 | 1270 - 1420 | 1400 - 1550 | 1540 - 1690 | 1580 - 1730 |

Table of mechanical properties of high fatigue class (the strength of the same plate is not greater than 40MPa)

| Diameter(mm) | Tensile Strength/MPA | Reduction of area/% ≥ |

| VDC | VDCrV-A | VDCrV-B | VDSiCr |

| 0.50-0.80 | 1700-2000 | 1750-1950 | 1910-2060 | 2030-2230 | - |

| 0.80-1.00 | 1700-1950 | 1730-1930 | 1880-2030 | 2030-2230 | - |

| 1.00-1.30 | 1700-1900 | 1700-1900 | 1860-2010 | 2030-2230 | 45 |

| 1.30-1.40 | 1700-1850 | 1680-1860 | 1840-1990 | 2030-2230 | 45 |

| 1.40-1.60 | 1670-1820 | 1660-1860 | 1820-1970 | 2000-2180 | 45 |

| 1.60-2.00 | 1650-1800 | 1640-1800 | 1770-1920 | 1950-2110 | 45 |

| 2.00-2.50 | 1630-1780 | 1620-1770 | 1720-1860 | 1900-2060 | 45 |

| 2. 50-2.70 | 1610-1760 | 1610-1760 | 1690-1840 | 1890-2040 | 45 |

| 2.70-3.00 | 1590-1740 | 1600-1750 | 1660-1810 | 1880-2030 | 45 |

| 3.00-3.20 | 1570-1720 | 1580-1730 | 1640-1790 | 1870-2020 | 45 |

| 3.20-3.50 | 1550-1700 | 1560-1710 | 1620-1770 | 1860-2010 | 45 |

| 3.50-4.00 | 1530-1680 | 1540-1690 | 1570-1720 | 1840-1990 | 45 |

| 4.20-4.50 | 1510-1660 | 1520-1670 | 1540-1690 | 1810-1960 | 45 |

| 4.70-5.00 | 1490-1640 | 1500-1650 | 1520-1670 | 1780-1930 | 45 |

| 5.00-5.60 | 1470-1620 | 1480-1630 | 1490-1640 | 1750-1900 | 40 |

| 5.60-6.00 | 1450-1600 | 1470-1620 | 1470-1620 | 1730-1890 | 40 |

| 6.00-6.50 | 1420-1570 | 1440-1590 | 1440-1590 | 1710-1860 | 40 |

| 6.50-7.00 | 1400-1 550 | 1420-1570 | 1420-1570 | 1690-1840 | 40 |

| 7.00-8.00 | 1370-1 520 | 1410-1560 | 1390-1540 | 1660-1810 | 40 |

| 8.00-9.00 | 1350-1 500 | 1390-1540 | 1370-1520 | 1640-1790 | 35 |

| 9.00-10.00 | 1340-1490 | 1370-1520 | 1340-1490 | 1620-1770 | 35 |

Hot Tags: China,custom , Oil tempered spring steel wire , manufacturer,factory,supplier

Contact us with any questions

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek