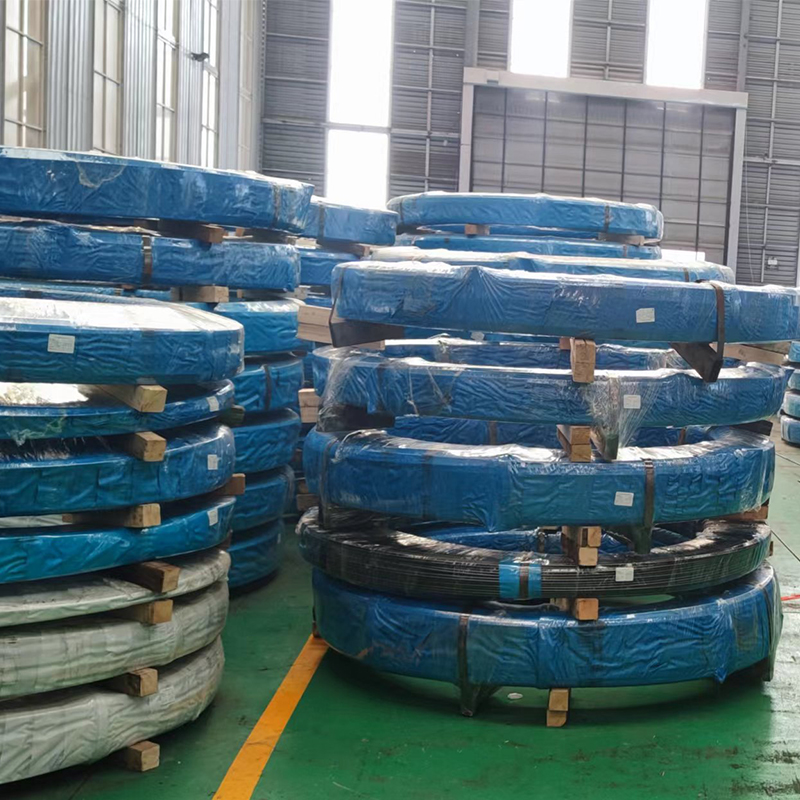

Our company have been in spring steel wire business for more than ten years, we are internationally experienced, professional, and we can provide variety of spring steel wire products with high quality to our clients.

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek