OT Wire containing C, Si is selectively added by the predetermined amounts of V, Cr, and Cu. our OT Wire shows ecellent performance which is not available in high carbon spring wire and music wire. OT Wire has superior strength and toughness. It will implement excellent elasticity, ductility, better resistance against fatigue and deformation in various spring applications. OT Wire is recommended to make the springs for repeated dynamic loads, including clutch springs.

1. Classification, code, diameter range of steel wire and the corresponding relationship with steel grade

| Classification | Static state | Medium fatigue | High fatigue | Grade |

| Tensile Strength | Low Strength | FDC | TDC | VDC | 65、70、65Mn |

| Medium Strength | FDCrV(A、B) | TDCrV(A、B) | VDCrV(A、B) | 50CrVA、67CrV |

| FDSiMn | TDSiMn | | 60Si2Mn、60Si2MnA |

| High Strength | FDCrSi | TDCrSi | VDCrSi | 55CrSi、SAE9254V |

| Diameter | 0.5mm~17.0mm | 0.5mm~17.0mm | 0.5mm~10.0mm | |

Note 1: Static grade steel wire is suitable for general purpose spring, which is expressed as FD, Note 2: medium fatigue grade steel wire is suitable for clutch spring, suspension spring, shock absorbing coil spring, etc., which is expressed as TD. Note 3: High fatigue grade steel wire is used in the occasion of intense movement, such as engine valve spring, valve spring, expressed as VD. |

|

|

2. Steel wire diameter control range

| Diameter(mm) | Tolerance(±) | Diameter(mm) | Tolerance(±) |

| TD VD | FD | | TD FD | VD |

| 0.50 - 0.80 | 0.01 | 0.015 | 5.50 - 7.00 | 0.035 |

| 0.80 - 1.00 | 0.015 | 0.02 | 7.00 - 9.00 | 0.035 |

| 1.00 - 1.80 | 0.02 | 0.025 | 9.00 - 10.00 | 0.04 |

| 1.80 - 2.80 | 0.025 | 0.03 | 10.00 - 11.00 | 0.04 |

| 2.80 - 4.00 | 0.03 | 11.00 - 14.50 | 0.05 |

| 4.00 - 5.50 | 0.03 | 14.50 - 17.00 | 0.05 |

Note: The non-roundness is not more than half of the allowable deviation of the size

3. Steel wire surface inspection

The surface of the steel wire is smooth, and there should be no scratches, rust, folding, stuttering and other defects that may have harmful effects on the use of the steel wire. The maximum depth is allowed to not exceed the bottom

Table specifies depth of defects. VD grade, TD grade steel wire shall not be fully decarbonized, but allow not more than d1.0% of the partial decarbonization.

The maximum depth allowed for surface defects

| Diameter(mm) | VD | TD | FD |

| 0.50~2.00 | 0.01mm | 0.015mm | 0.02mm |

| 2.00~6.00 | 0.5%d | 0.8%d | 1.0%d |

| 6.00~10.10 | 0.7%d | 1.0%d | 1.4%d |

| 10.00~17.00 | - | 0.10mm | 0.20mm |

4. Heat treatment

After coiling, the spring should be tempered between 380 ° C and 420 ° C to reduce the surface stress, and after shot blasting, it should be hot pressed or stress relieved at 250 ° C.

5. Delivery status

Oil hardening-tempering

6. Delivery form

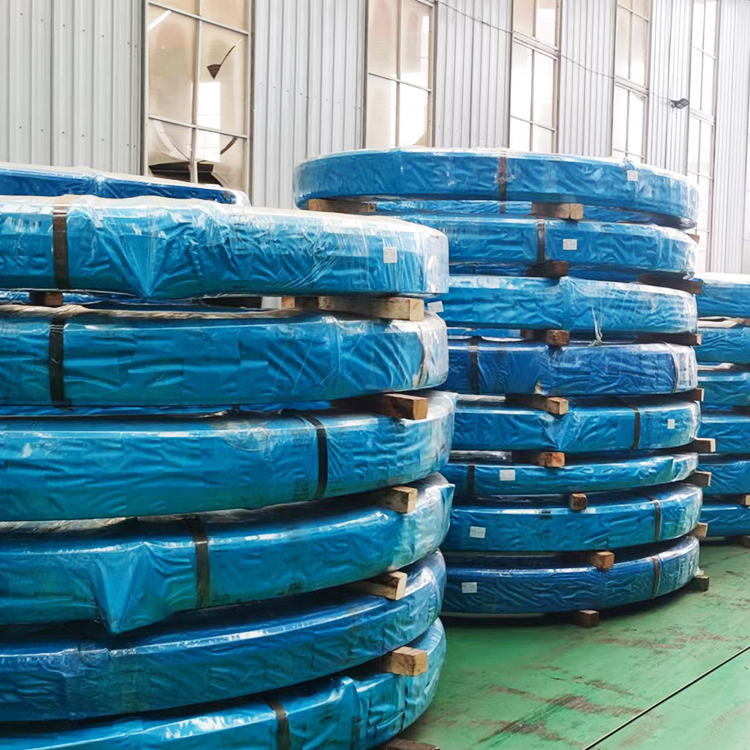

The steel wire is delivered in coil form

Hot Tags: China,custom , OT Wire , manufacturer,factory,supplier

Contact us with any questions

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek