HAYNES ® 230 alloy is a nickel chromium tungsten molybdenum alloy that combines excellent high-temperature strength, oxidation resistance, long-term thermal stability, and good machinability.

Haynes 230 alloy material features:

1. High temperature strength, thermal stability, environmental resistance

230 alloy contains nickel, chromium, tungsten, and molybdenum, and has excellent high-temperature strength. Even when exposed to a high temperature environment of 1149 ° C for a long time, it has outstanding oxidation resistance, especially in nitriding environments, and has very good long-term thermal stability. This material can be machined, formed, processed, and cast. Compared to other high-temperature alloys, 230 alloy has lower thermal expansion characteristics and can withstand particle coarsening for a long time under high temperature conditions.

2. Easy to process

230 alloy has good formability and welding performance. It can be forged, and if the high temperature is long enough to reach 1177 ° C for the entire workpiece, it can also be hot worked. Due to its good ductility, 230 alloy can be cold formed. Whether it is hot or cold processing, the finished parts need to be annealed and rapidly cooled to restore the optimal performance of the material. This alloy can be welded using various methods, including GTAW (tungsten inert gas welding), GMAW (metal inert gas welding), and resistance welding.

3. Heat treatment

The supply state of 230 alloy is usually forged solid solution. The temperature range for solution treatment is 1177-1246 ° C, followed by rapid cooling or water quenching to achieve optimal performance. If the annealing temperature is lower than the solution temperature, carbide precipitation will occur, which will affect the strength and ductility of 230 alloy.

| Haynes 230 Chemical Element Composition Content (%) |

| Component | Fe | C | Si | Mn | Cr | Ni | Mo | Ti | W | Nb | B | Co | Al | La |

| Minimum value | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Maximum value | 3 | - | - | - | - | - | - | 0.1 | - | 0.5 | 0.015 | 5 | - | - |

| Nominal value | - | 0.1 | 0.4 | 0.5 | 22 | 57 | 2 | - | 14 | - | - | - | 0.3 | 0.02 |

4. Casting

230 alloy can be cast using traditional sand casting or vacuum investment casting. It is recommended to adopt the upper limit value of the silicon liquid level range in the standard to improve fluidity. According to performance requirements, cast parts can be in both cast and solution states.

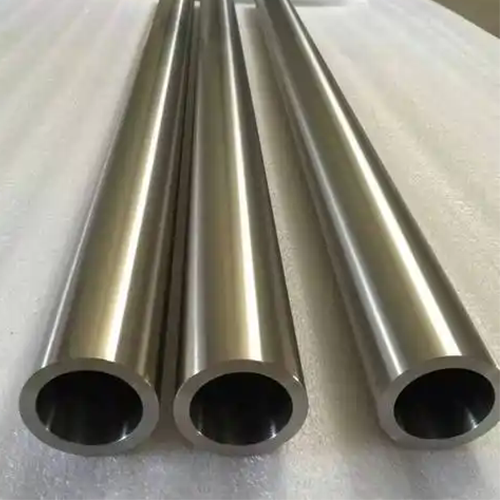

5. Multiple supply shapes

The supply shapes of 230 alloy include thick plates, thin plates, strips, foils, blocks, round bars, wires, welded products, and pipe materials

6. Application

The excellent comprehensive performance of 230 alloy enables it to be widely used in the aviation and energy industries, such as combustion chambers, relay ducts, flame stabilizers, thermocouple protective sleeves, and other gas turbine components. In the chemical industry, catalyst grid frames made of 230 alloy are placed in nitrogen burners, as well as high-strength thermocouple protective sleeves, high-temperature heat exchangers, pipelines, high-temperature corrugated pipes, etc.

In the industrial electric heating industry, 230 alloy has various applications, such as manufacturing furnace chambers, fixtures, and flame protection covers for combustion chambers,

Heat exchanger inner shell, air damper, nitriding furnace inner shell, baskets, grilles, trays, etc. for heat treatment.

Hot Tags: China,custom , HAYNES ® 230 (Hastelloy 230) , manufacturer,factory,supplier

Contact us with any questions

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek