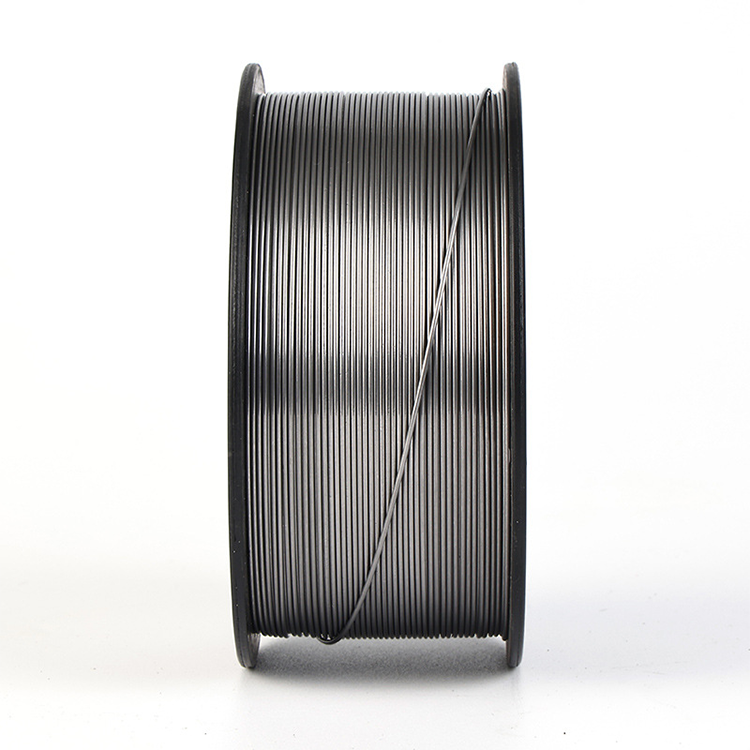

The chemical composition of ER50-6 welding wire steel wire rod has been carefully designed to ensure its excellent performance. Its carbon content is moderate, which not only endows the wire rod with sufficient strength but also avoids the increased sensitivity to welding cracks caused by a too high carbon content. The reasonable addition of manganese element greatly enhances the deoxidation ability of the material, effectively reduces the oxygen content in the weld seam, and further improves the quality of the weld seam, making the welded joint more firm and reliable. At the same time, the contents of impurity elements such as silicon, sulfur, and phosphorus are strictly controlled at an extremely low level, minimizing the adverse effects on the welding performance and ensuring the stability of the welding process and the purity of the weld seam.

The ER50-6 welding wire steel wire rod exhibits remarkable strength characteristics. It can withstand a large tensile stress and is not prone to breakage during the welding process, providing a strong guarantee for the welding of complex structures. At the same time, its toughness performance is equally excellent. Even in a low-temperature environment or when subjected to impact loads, it can effectively prevent brittle fracture and ensure the safety and durability of the welded part.

The ER50-6 welding wire steel wire rod has undergone professional rolling and processing techniques, featuring excellent electrical conductivity and stability. When the welding current passes through, relying on its good electrical conductivity, this wire rod can ensure the uniform distribution of the current, making the welding arc burn stably, reducing welding spatter, and improving the quality of the welded shape. Moreover, during the long-term welding thermal cycle process, the ER50-6 wire rod can still maintain its structural stability, without obvious organizational transformation or performance degradation, thus continuously and stably producing high-quality welding results.

The ER50-6 welding wire steel wire rod shines brightly in numerous industries due to its excellent performance. In the field of architectural steel structures, it is used for the welding of steel beams and columns in large stadiums and high-rise buildings to ensure the structural stability; in mechanical manufacturing, it is indispensable for the assembly and welding of various mechanical equipment components, helping the equipment operate efficiently; it is widely used in the automotive manufacturing industry. From the welding of the vehicle body frame to engine components, it ensures the lightweight and safety of the vehicle; in shipbuilding, it is used for the splicing of hull steel plates, enabling the ship to withstand the erosion of seawater and the impact during navigation.

By choosing the ER50-6 welding wire steel wire rod, whether facing a harsh industrial environment or pursuing the ultimate process standards, it can, with its own excellent quality, become a powerful assistant for your welding projects.

Hot Tags: China,custom , ER50-6 welding wire steel wire rod , manufacturer,factory,supplier

Contact us with any questions

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek