Bonded silver wire is a high-performance material widely used in the semiconductor field and other areas. The following will provide a detailed introduction from aspects such as its characteristics, applications, preparation, and market development.

Bonded silver wire is a kind of metal wire used in fields such as semiconductor packaging. It is mainly made of high-purity silver, and the purity usually reaches 99.99% or higher.

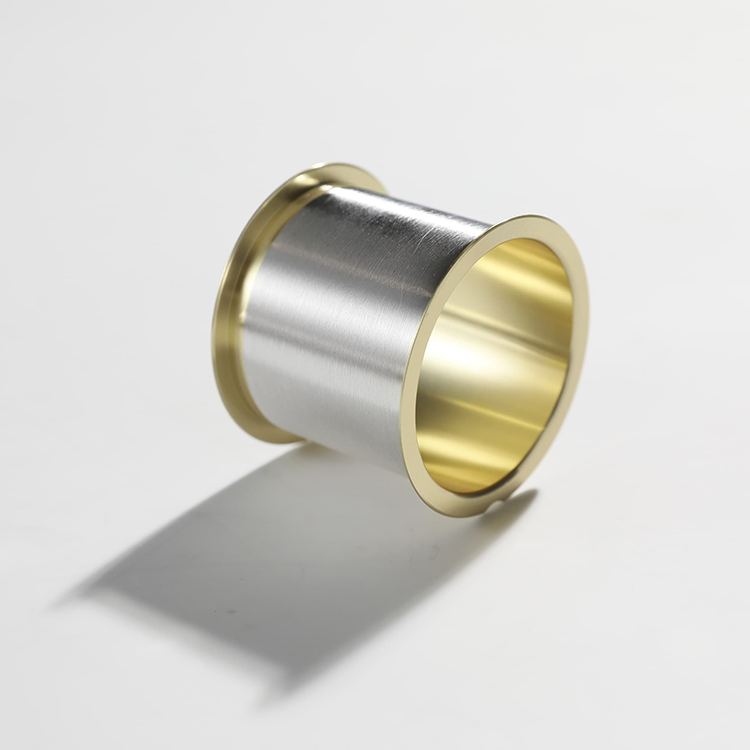

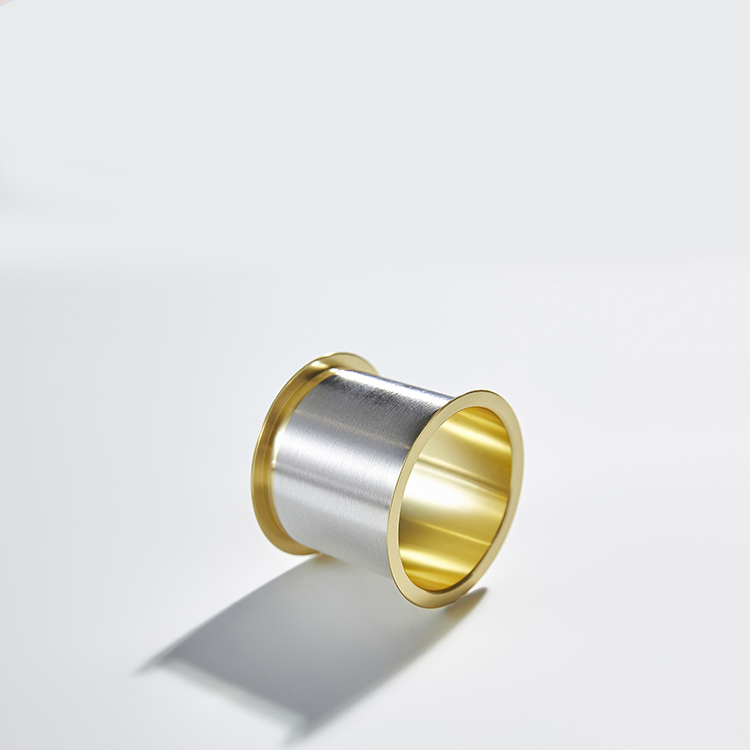

Appearance: It is usually in the form of a slender wire, with a smooth surface and a very small diameter, generally ranging from 15 micrometers to 75 micrometers.

Silver alloy Bonding Wire AG99%

| Type | φ Diameter±1% um | Breaking Load BL(gf) | Elongation EL(%) | Length Meters |

| YF-99 | 18(0.7mil) | >4 | 3-20 | 500/1000 |

| 99B | 20(0.8mil) | >5 | 3-20 | 500/1000 |

| SW-21 | 23(0.9mil) | >7 | 3-20 | 500/1000 |

| 99A | 25(1.0mil) | >8 | 3-20 | 500/1000 |

| 99A | 30(1.2mil) | >11 | 3-20 | 500/1000 |

Performance Characteristics:

Excellent electrical conductivity: Silver has an extremely high electrical conductivity. Bonded silver wire can transmit current quickly and efficiently, ensuring stable electrical connections between various components in electronic devices and reducing signal transmission delays.

Good thermal conductivity: It can effectively dissipate the heat generated by electronic components such as chips during operation, preventing the performance degradation or damage of components due to overheating, and improving the reliability and stability of the equipment.

Good bonding performance: In the bonding process of semiconductor packaging, under the action of heat and pressure, it can form a strong metal bond with the metal pads on the surface of semiconductor devices, ensuring the reliability and stability of the connection.

Cost advantage: Compared with traditional bonded gold wire, bonded silver wire has a relatively lower price while meeting most of the performance requirements. It can effectively reduce the production costs of industries such as semiconductor packaging and improve the market competitiveness of products.

Application Fields:

Semiconductor packaging: It is a commonly used internal lead material in the microelectronic packaging of semiconductor discrete devices, light-emitting diodes (LEDs), integrated circuits (ICs), etc., and is used to achieve the electrical connection between the chip and the lead frame.

Electronic component manufacturing: During the manufacturing process of electronic components such as resistors, capacitors, and inductors, bonded silver wire can be used to connect the electrodes and pins of the components, ensuring the normal operation of the components.

Communication field: It can be used to manufacture communication devices such as antennas and filters, which helps to improve the stability and speed of signal transmission.

Preparation Process:

Smelting: After uniformly mixing high-purity silver raw materials and alloying elements or dopants added as needed, they are placed in a vacuum melting furnace and smelted under high temperature and high vacuum conditions to obtain a silver alloy melt with a uniform composition.

Wire drawing: Heat the silver alloy ingot obtained from smelting to an appropriate temperature, and perform multiple stretches through a wire drawing machine to gradually reduce the diameter of the wire material to meet the required size requirements. During the wire drawing process, parameters such as the drawing speed and tension need to be controlled to ensure the dimensional accuracy and surface quality of the wire material.

Annealing: Perform an annealing treatment on the bonded silver wire after wire drawing to eliminate the internal stress generated by stretching in the wire material, improve the microstructure and performance of the wire material, and enhance its flexibility and ductility, making it more suitable for subsequent bonding processes.

Market Development

Demand growth: With the rapid development of the electronic information industry, the market demand for products such as semiconductor devices, LEDs, and integrated circuits is constantly increasing, driving the growth of the bonded silver wire market.

Technological innovation: In order to meet the increasing performance requirements and the need to reduce costs, the production enterprises of bonded silver wire are constantly carrying out technological innovation and developing bonded silver wire products with higher performance and more stable quality. The application of technologies such as doping modification and surface coating has further improved the comprehensive performance of bonded silver wire.

Hot Tags: China,custom , Bonded silver wire , manufacturer,factory,supplier

Contact us with any questions

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek