65Mn GB /T 1222-2016 Spring steels wire is mainly composed of carbon (C), manganese (Mn) and other alloying elements, of which the carbon content is about 0.62%, the manganese content is adjusted according to specific needs. In addition, it also contains a small amount of silicon, phosphorus, sulfur and other elements, and its chemical composition should comply with the provisions of GB/T 13013-91 (or similar updated standards).

| Material designation | 65Mn |

| China ISC | U21653 |

| Correspondence standard | GB /T 1222-2016

Spring steels |

| Brand/Supply source | China -> Henan |

| Sort out | Spring steel |

| Property | Flexible and easy machinability hardenability |

| Tag | High quality carbon structural steel |

| Instructions | The steel is a very widely used spring steel grade, high strength, good hardenability and comprehensive mechanical properties, small decarbonization tendency, good cutting performance, and low price. However, it has overheating sensitivity and tempering brittleness, and it is easy to appear quenching crack. Poor corrosion resistance.

For slightly larger ordinary springs, such as 5~10mm leaf springs and wire diameter 1~15mm coil springs, can also be used as spring rings, valve springs, spring, shock absorbers and clutch reeds, as well as cold coil springs made of drawing steel wire

65Mn is widely used in the fastener industry, can produce all kinds of spring washers, elastic cylindrical pins and some elastic rings, etc., a small amount of nuts. No bolts, screws and conventional washers.

Recommended selection: All kinds of spring washers, pins and clasp, etc., working in a non-corrosive environment, strength 40~54HRC, recommended selection. |

| Density | 7.18 g/cm3 |

Physical properties:

Strength and hardness: 65Mn spring steel wire has high strength and hardness, and can withstand large loads and deformation.

Elasticity and toughness: The material also has good elasticity and toughness, and can quickly return to the original shape after external force, while not easy to break.

Wear resistance and corrosion resistance: 65Mn spring steel wire has excellent wear resistance and corrosion resistance, and can maintain stable performance in harsh environments.

65Mn Chemical element content (%)

| Component | C | Si | Mn | P | S | Cr | Ni | Cu |

| Minimum value | 0.62 | 0.17 | 0.9 | - | - | - | - | - |

| Maximum value | 0.7 | 0.37 | 1.2 | 0.03 | 0.03 | 0.25 | 0.35 | 0.25 |

Production process:

The production process of 65Mn spring steel wire includes raw material preparation, smelting, rolling, heat treatment, drawing and surface treatment. Among them, heat treatment is one of the key steps, through quenching and tempering treatment can improve the strength and toughness of the steel wire. Specifically, the quenching temperature is usually 830±10℃, and the oil is cooled; The tempering temperature is 540℃±10℃, and the water or oil is cooled.

65Mn mechanical properties

| Heat treatment/delivery status | Tensile strength

σb

Mpa | Yield point

σs

Mpa | Elongation or elongation after breaking

δ

% | Shrinkage of section

ψ

% | Hardness

HBW |

| Quenching and tempering | ≥980 | ≥785 | ≥8 | ≥30 | - |

| Hot rolling (WHR) | - | - | - | - | ≤302 |

① The mechanical properties in the table are applicable to bars with a diameter or side length not greater than 80mm and flat steel with a thickness not greater than 40mm. For bars with diameter or side length greater than 80mm and flat steel with thickness greater than 40mm, the elongation and section shrinkage after fracture are allowed to be reduced by 1% (absolute value) and 5% (absolute value), respectively, compared with the provisions in the table.

② The mechanical properties of the rod are usually not tested. If the demander requires to test the mechanical properties, the specific indicators shall be determined by the demander and the demander through negotiation

Application field

Because 65Mn spring wire has excellent physical properties and processing properties, it is widely used in the manufacture of various springs, such as automotive suspension springs, industrial machinery support springs and shock absorbing springs. In addition, it can also be used to manufacture high wear resistance parts, such as grinding machine spindles, spring clips, precision machine tool leads, etc.

Examples of machined fastener products

| 65Mn(GB 1222/4358/3525;YB 5058加工的部分产品 |

| name | Model number | Performance class | specification |

| Conical lock washers for assemblies | GB 9074.28-1988 | 40~50HRC | 5~8 |

| Spring washers for assemblies | GB 9074.26-1988 | 42~50HRC | 2.5~12 |

| Tapered serrated lock washer | GB 956.2-1987 | 40~50HRC | 3~5 |

| Elastic retainer for shaft | GB 894.1-1986 | 47~54HRC | 3~85 |

| Wire retaining ring for shaft | GB 895.2-1986 | - | 4~35 |

| Hole with wire ring | GB 895.1-1986 | - | 7~65 |

| Elastic retainer for hole | GB 893.1/.2 | 47~54HRC/44~51HRC | 3~200 |

| Standard spring washer | GB 93-1987 | 42~50HRC | 2~27 |

| Corrugated elastic washer | GB 955-1987 | 40~50HRC | 3~12 |

| Saddle shaped elastic washer | GB 860-1987 | - | 2~8 |

| Retaining nut | GB 805-1988 | 30~40HRC | 6~48 |

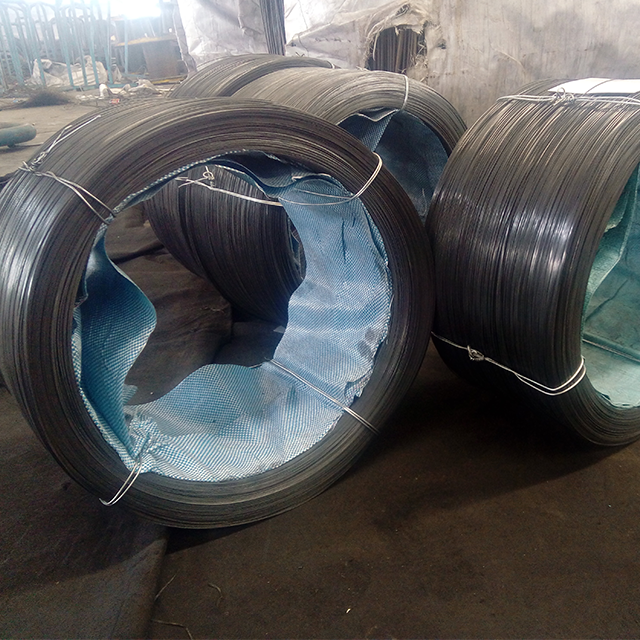

Hot Tags: China,custom , 65Mn GB /T 1222-2016 Spring steels wire , manufacturer,factory,supplier

Contact us with any questions

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek